Introduction to 3D Printing

Understanding 3D Printing Technologies

Explanation of different 3D printing methods:

SLA (Stereolithography)

SLS (Selective Laser Sintering)

FDM (Fused Deposition Modeling)

Comparison of these technologies in terms of materials, accuracy, and cost.

Applications of 3D Printing

1.Industry use cases: automotive, aerospace, healthcare, and consumer products.

2.Examples of innovative projects and products created with 3D printing.

Benefits of 3D Printing

1.Customization and personalization capabilities.

2.Reduction in waste and material usage.

3.Speed and efficiency in prototyping and production.

Challenges and Considerations

1.Limitations in terms of material strength and finish.

2.The learning curve for new users and the importance of design skills.

Future Trends in 3D Printing

1.Emerging materials and technologies.

2.The role of 3D printing in sustainable manufacturing.

Conclusion

1.Recap of the transformative impact of 3D printing.

2.Encouragement to explore 3D printing for personal or business innovation.

Understanding 3D Printing Technologies

At the heart of 3D printing are several distinct technologies, each with its unique advantages. Stereolithography (SLA) uses a laser to cure liquid resin into solid parts, offering high precision and smooth surface finishes. Selective Laser Sintering (SLS) employs a laser to fuse powdered material, enabling the creation of durable and complex geometries without support structures. Fused Deposition Modeling (FDM), the most accessible and widely used method, extrudes thermoplastic filaments layer by layer, making it ideal for prototypes and functional parts.

Applications of 3D Printing

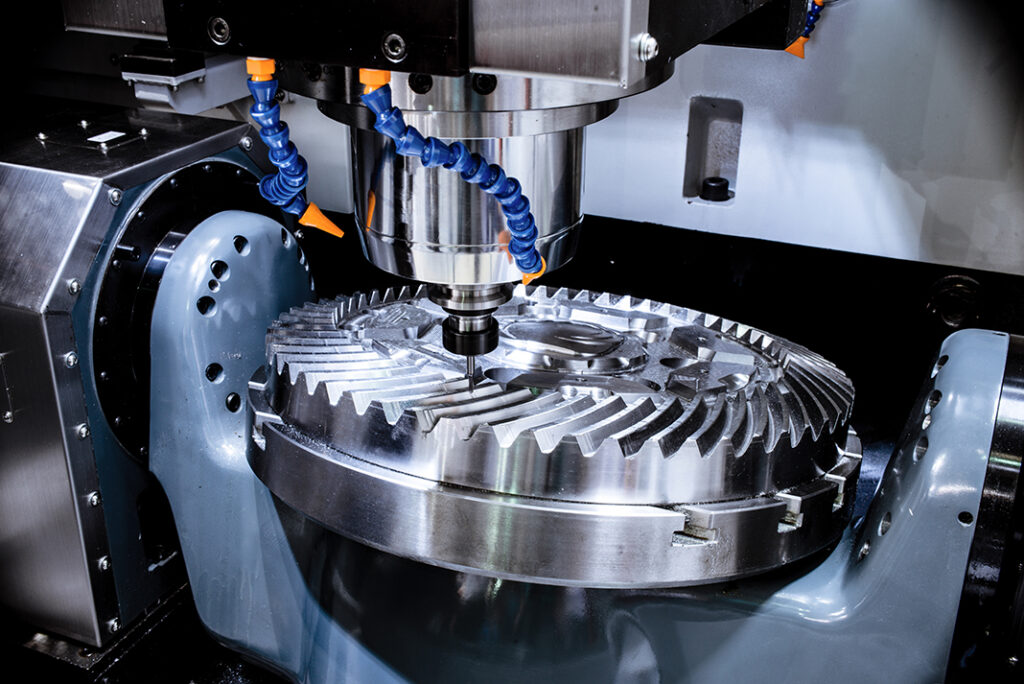

The applications of 3D printing span across various industries. In automotive and aerospace, it facilitates the production of lightweight components and complex assemblies. The healthcare sector benefits from custom prosthetics and bioprinting innovations. Consumer products, from fashion to electronics, are increasingly leveraging 3D printing for bespoke designs and rapid market entry. Notable examples include 3D-printed shoes, medical implants, and even entire houses.

Benefits of 3D Printing

One of the most significant advantages of 3D printing is its ability to deliver highly personalized products tailored to individual needs. It minimizes waste by using only the necessary material, promoting sustainable practices. The speed and efficiency of 3D printing in prototyping accelerate the design process, enabling faster iterations and time-to-market.

Challenges and Considerations

Despite its advantages, 3D printing faces certain challenges. The strength and finish of printed parts may not always match those produced by traditional methods. There is also a learning curve associated with mastering 3D design software and understanding the nuances of each printing technology.

Future Trends in 3D Printing

Looking ahead, the future of 3D printing is bright with promise. Advancements in materials, such as biodegradable and conductive filaments, are expanding its capabilities. As the technology evolves, 3D printing is poised to play a crucial role in sustainable manufacturing, reducing carbon footprints and enabling localized production.

Conclusion

3D printing is not just a tool; it’s a transformative force in modern manufacturing. Its ability to turn digital designs into tangible objects opens up endless possibilities for innovation. Whether you’re a business looking to streamline production or a hobbyist eager to explore new creative avenues, 3D printing offers a world of opportunity waiting to be discovered.